Hydraulic torque wrenches are critical tools in industries requiring precision bolting, such as oil and gas, manufacturing, power generation, and heavy construction.

These tools ensure the accurate application of torque to fasteners, making them indispensable in high-stakes environments where even minor errors can have significant consequences. As these industries evolve, so do the tools they rely on.

Recent developments in hydraulic torque wrenches, particularly for square drive and hexdrive types, are geared toward improving efficiency, safety, and data precision.

Let’s dive into the latest trends in the design and application of hydraulic torque wrenches, highlighting how manufacturers are pushing the boundaries of innovation to meet growing industrial demands.

Introduction to Hydraulic Torque Wrenches

Hydraulic torque wrenches are designed to provide precise torque application, making them ideal for critical applications where traditional hand tools would fall short. Hydraulic torque wrenches work by applying high levels of torque to fasteners, allowing for uniform and secure tightening.

Types of Hydraulic Torque Wrenches

There are two types of hydraulic torque wrenches: square drive and hexdrive type

Square Drive Wrenches:

These are the most common type and are versatile, suitable for a broad range of bolting applications. They use interchangeable sockets to apply torque to nuts or bolts of various sizes.

Hexdrive Wrenches:

Also known as direct fit wrenches, these tools are used for specific applications that require direct access to hexagonal nuts, often in tight spaces where a socket might not fit.

As industries expand and become more complex, the demand for enhanced hydraulic torque wrenches are increasing, leading to several key trends shaping the future of these tools.

Key Trends in Hydraulic Torque Wrenches

Increased Automation for Enhanced Efficiency

Automation has become a part of almost every industrial process, and hydraulic torque wrenches are no different. Modern wrenches are integrating automated features to reduce the reliance on manual operations.

These tools make it quicker and easier to apply the right amount of torque, which speeds up the entire bolting process and makes it more efficient.

Smart Tools: Torque wrenches are increasingly equipped with digital controls, allowing users to preset torque values and automatically stop the wrench when the desired torque is achieved. This not only speeds up the process but also eliminates human error in torque settings.

Automation of Calibration: New models include automatic calibration features, which ensure that the tool remains accurate over time. This trend addresses one of the major challenges in torque wrench use: calibration drift, which can lead to inaccurate bolting.

Automation is particularly advantageous in environments where speed and precision are paramount, such as large-scale construction or offshore oil platforms.

Lightweight and Ergonomic Designs

Portability and ease of use are increasingly critical in the design of hydraulic torque wrenches. Many jobs require workers to operate these tools in confined or difficult-to-reach areas, making it essential for wrenches to be both compact and lightweight.

In response, manufacturers have developed wrenches with advanced materials and ergonomic features.

- Advanced Materials: High-strength, lightweight materials such as titanium and advanced alloys are being used to reduce the overall weight of torque wrenches without compromising their durability or power. This makes the tools easier to handle, especially in confined spaces or during long work shifts.

- Ergonomic Features: Design improvements now focus on user comfort. Modern wrenches are equipped with ergonomic handles and reduced vibration mechanisms to minimize user fatigue and the risk of repetitive strain injuries. These features are especially beneficial for industries where operators use the tools for extended periods.

The trend toward lighter and more ergonomic tools is also driving innovation in the development of compact, portable pumps to power hydraulic torque wrenches. This not only reduces the physical strain on workers but also ensures better productivity in tight or elevated workspaces.

Improved Durability and Longevity

Given the extreme environments in which hydraulic torque wrenches are often used, durability has always been a priority.

However, recent developments are taking this even further, with manufacturers focusing on creating tools that can withstand harsher conditions and last longer between maintenance cycles.

- Corrosion Resistance: The use of corrosion-resistant materials in the construction of wrenches is now a standard feature, especially for tools? used in maritime, offshore, or chemically aggressive environments. Protective coatings and treatments are also applied to prolong the life of these tools.

- Enhanced Sealing Mechanisms: To further extend the longevity of hydraulic wrenches, manufacturers have developed advanced sealing systems that prevent the ingress of dust, moisture, and other contaminants. This reduces the need for frequent maintenance and minimizes tool downtime.

These durability enhancements not only increase the service life of the tools but also contribute to a reduction in long-term operational costs.

Integration with Digital Monitoring Systems

As digitalization spreads through industrial operations, hydraulic torque wrenches are becoming smarter, offering real-time data tracking and monitoring. This trend is particularly important in industries that require documentation and proof of proper torque application.

- Torque Monitoring: Advanced hydraulic torque wrenches now come with integrated sensors that monitor the torque applied during operation. This data is transmitted to a central system or a handheld device, allowing operators to ensure that each fastener is tightened to the correct specification.

- Data Logging for Compliance: Many industries, such as oil and gas or aerospace, have strict regulations regarding bolt tightening and torque verification. With the integration of digital data logging, these industries can maintain a clear audit trail of torque application, ensuring compliance with safety standards and regulations.

This trend is expected to continue, as more companies prioritize traceability and documentation of maintenance procedures to ensure operational safety and integrity.

Focus on Safety

Safety has always been a paramount concern in heavy industrial applications, and the latest generation of hydraulic torque wrenches reflects this.

Manufacturers are introducing features that not only protect the tool but also the operators who use them.

- Pressure Relief Valves: These mechanisms are designed to automatically relieve excess pressure within the hydraulic system, preventing overloading and potential tool failure. This ensures the tool operates within safe parameters, reducing the risk of injury or damage.

- Low Vibration Design: High torque levels often generate significant vibration, which can cause operator fatigue and even long-term health issues such as hand-arm vibration syndrome (HAVS). New torque wrenches are being designed to minimize vibration, enhancing user comfort and safety.

Safety-focused innovations help reduce workplace accidents and contribute to more efficient bolting operations.

Shift Toward Sustainable Hydraulic Torque Wrenches

The push towards sustainability is reshaping the hydraulic tool landscape, sparking a demand for torque wrenches that are both energy-efficient and eco-conscious. As a result, greener alternatives are emerging, designed to reduce environmental impact without compromising performance.

Comparing Square Drive and Hexdrive Wrenches

Both square drive and hexdrive hydraulic torque wrenches serve distinct purposes in industrial applications. While square drive wrenches are more versatile and widely used for general bolting tasks, hexdrive wrenches are designed for specialized applications, particularly in confined or awkward spaces.

- Square Drive: These wrenches are equipped with interchangeable sockets, making them ideal for a variety of bolt sizes. Their versatility allows them to be used across multiple industries, from construction to power generation.

- Hexdrive: Also known as low-profile wrenches, hexdrive tools are tailored for applications where space is limited, such as in refineries or petrochemical plants. Their slimmer design allows them to fit into tight spaces where traditional sockets would be too bulky.

Each type of wrench offers unique advantages, and the choice between them often depends on the specific requirements of the application.

Conclusion

The development of hydraulic torque wrenches is being shaped by trends such as increased automation, improved materials, digital integration, and enhanced safety features.

Both square drive and hexdrive wrenches are benefiting from these advancements, allowing industries to achieve greater precision, efficiency, and safety in their bolting operations. As technology continues to evolve, these tools will remain critical in driving productivity and ensuring the integrity of industrial applications.

With all these advancements, your hydraulic torque wrench might just become your new best friend: just don’t expect it to grab you a ☕ coffee!

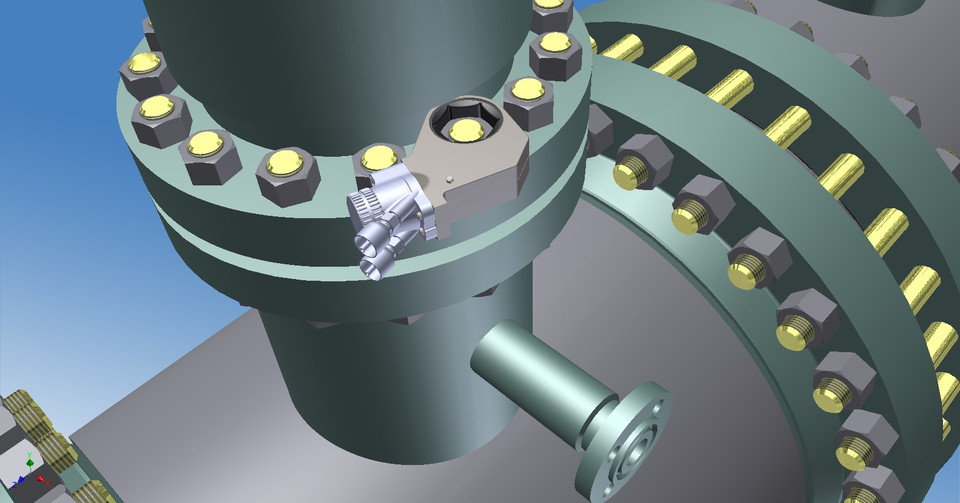

Featured Image and 3D-Model Source: GrabCAD Hydraulic Torque Wrenches

Leave a Reply